The centrifugal force experienced by the car tries to throw it away from the turning center. The centripetal force is experienced in the form of friction on tyres. Hence, it experiences equal and opposite centripetal & centrifugal forces. When the vehicle turns on a corner, it performs a circular motion. Providing Negative Camber improves the cornering performance. Negative Camber is encountered when the top of the wheels lean inwards. The vehicle is said to have zero Camber when the wheels stand perfectly straight on the ground. This is because the heavy load on these vehicles cause outward leaning wheels to straighten up, improving the vehicle stability.

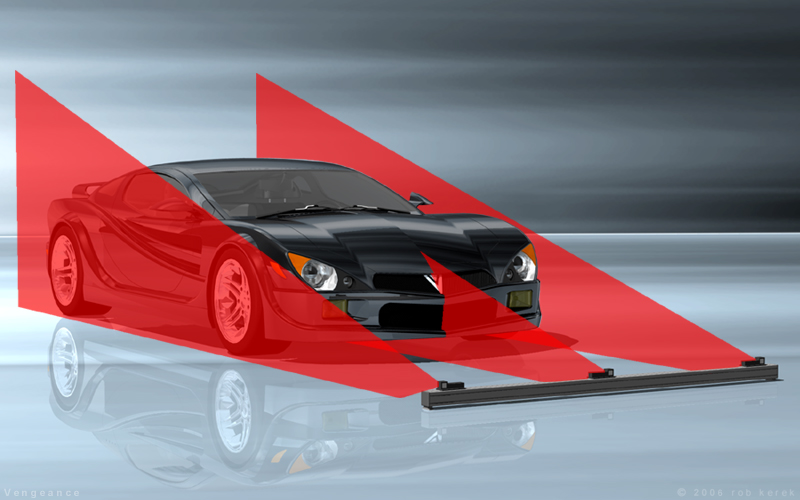

Positive Camber is also provided in load carrying vehicles. This is because, it improves the steering response and decreases the steering efforts required for turning the vehicle. Positive Camber is generally used in off-road vehicles. The Camber would be called positive when the top of the wheels lean outwards. Depending upon wheel orientation, Camber can be of three types. Generally a Camber around 0.5-2 degrees is given on the vehicles. This angle is very important for the cornering performance of the vehicles. Camber Ĭamber is the angle which the vertical axis of the wheel makes with the vertical axis of the vehicle. These cameras perform the same function as the other style of alignment equipment, yet alleviate numerous issues prone to relocating a heavy precision camera assembly on each vehicle serviced. This system flashes one array of LEDs for each reflector whilst a camera centrally located in the LED array "looks for" an image of the reflectors patterned face.

In this case, the alignment "tower" contains the cameras as well as arrays of LEDs. Often with alignment equipment, these "heads" can be a large precision reflector. The camera units communicate their physical positioning with respect to other camera units to a central computer which calculates and displays. There are usually four camera units in a wheel alignment system (a camera unit for each wheel). Rake is the difference between the front and rear ride heights, a positive number when the rear ride height is larger.Ī camera unit (sometimes called a "head") is attached to a specially designed clamp which holds on to a wheel. An off-spec setback may occur because of a collision or a difference between right and left caster. There are some car models with different factory setting for right and left side wheelbase length, for various design reasons. This is because when the vehicle is turning, one wheel is ahead of the other by several centimetres and therefore the setback is negligible. Setback less than the manufacturer specified tolerance (for example about 6mm) does not affect car handling. Setback is the difference between right side and left side wheelbase length.

0 kommentar(er)

0 kommentar(er)